How To Identify The Quality Of A Sintered Nd-Fe-B Neodymium Magnet?

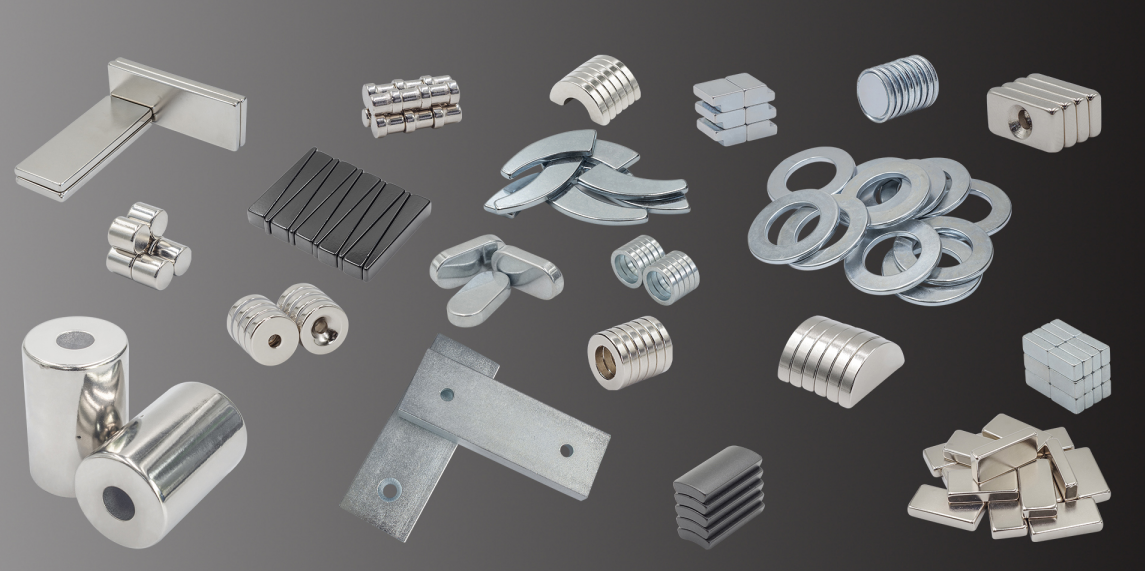

release time:10/25/2019 15:35:33Due to its cost-effectiveness, the sintered Nd-Fe-B neodymium magnet is widely used in many fields. Its applications include PC hard drives, magnetic resonance imaging (MRI), electric cars, magnetic levitation technique and consumer products like DVDs, mobile phones and speakers. Since it is required in nearly all fields in our modern society, it has become one of the most crucial components in driving the progression of advanced technology as well as our society.

Since the start of globalisation in 1985, the demand for permanent magnetic materials has also risen dramatically. The demand pushed the significant development of this market, and the applications have also broadened from industrial machinery to daily consumables. More magnet manufacturers enter the market to provide differentiated services and products. At the same time, the traditional industry leaders like JinTong Magnetic Materials Technology also seek to upscale their production capacity and improve product quality to offer competitive and professional plans to clients.

From the customers' perspectives, since they are having more choices in the market now, it becomes more difficult for them to pick the best quality Nd-Fe-B neodymium magnet from all those producers. Today, let's take a look at how we can identify a good quality magnet, based on three primary criteria.

Method 1: Magnet’s performance

To ensure the sintered Nd-Fe-B neodymium magnet can perform correctly, we must trace four significant aspects; they are the production of raw materials, the enterprise manufacturing requirements, its manufacturing technique as well as its ability to control magnetic orientation.

In term of raw materials, companies must follow national standards and provisions. Those documents clearly state which materials should be included, as well as how great the proportion should be to reach a certain level of quality. The provisions also help diversify whether the magnet is suitable for high-end usage or not.

These three aspects are purely based on the firm's ability to invest in machinery and perform tasks for clients. Industry leaders – such as JinTong – has invested in all kind of equipment and labour training to ensure they meet the highest standards. Its strict requirements and improved techniques have a direct impact on the magnet's properties. The advanced technology is positively related to the performance and quality of a magnet.

Method 2: Magnetic orientation

Regarding magnetic orientation, China is the only country that is capable of performing two-steps compression moulding. Firstly, the manufacturer applies a small pressure vertical moulding when it initiates the orientation process; then the second step is to use isostatic compaction to allow the magnetic orientation to become fixated and precise. Such a process is one of the most vital techniques in the Chinese magnet industry, and China is very proud of exclusively owning this world-leading crafting method.

Method 3: Production process monitoring

Supervision and control during the production process are crucial to ensure quality as well. We can inspect the thickness of the strip casting (SC) plates, or the size of the jet mill (JM) powder and its distribution to evaluate the quality.

JinTong believes that all superior products are made under the absolute control of quality; therefore, they also employ professionals and purchase related equipment for testings, and the results can prove all products reach national standards. Furthermore, with the advantage of accurate measurement, the alteration can be made much more manageable. Clients can also customise their orders based on Br, Hcb, Hcj and (BH)max according to their requirements.

Furthermore, the magnet's size and shape can determine the quality as well, and they are decided by their applications and work environments. A high-end neodymium magnet should contain a smooth surface while being precise in angles. Supervision, control and testing play critical roles here again as even the smallest discrepancy can cause inability to use the products.

Why we need a coating for Nd-Fe-B neodymium magnets

The most common and useful coating materials are nickel and zinc. Many customers know that a magnet requires at least one layer of electro-coating, but they do not understand why it is essential and their differences between different coatings. Let me tell you five aspects that differentiate a nickel-coated magnet from a zinc-coated one.

1.Polishing

Nickel performs better in creating a polished surface over zinc, and it also looks brighter. If clients have a higher requirement for the magnet's appearance, then nickel is recommended. Nickel layers are commonly applied to exported magnets as well.

2.Anti-corrosive

Nickel coating is more anti-corrosive than copper. It is not rusted even under 96H salt mist. On the other hand, a zinc coating magnet can be easily corrosive once it is over 48H.

3.Rigidity

When it is in use, a nickel-coated magnet has higher rigidity, which can prevent cracks and scratches, and minimise the possibility that the machinery needs to be repaired.

4.Product life

Due to the anti-corrosive characteristic and the rigidity, the overall product life is prolonged when the magnet uses nickel coating. Such an advantage also ensures the magnetic strength can be maintained for much longer than a zinc layer.

5.Price

In terms of costs, zinc has a significant advantage over nickel. However, all those benefits listed above are also sacrificed. The material costs and the technique required are two main reasons that lead to the difference in price.

Conclusion

Ultimately, the choice of a zinc or nickel coating is depends on how you use the magnets. If you are looking for the absolute best magnet, then an Nd-Fe-B neodymium magnet with nickel coating should be your choice. If you still have questions, feel free to ask experts in JinTong, and I am sure they can have a discussion and plan for your enterprise.

For more info, please visit: https://www.jintongmagnet.com

CN

CN

Consultation

Consultation Contact us

Contact us Announcement

Announcement